Since ancient times, the pursuit of human cutting tools has never stopped. From the original natural stone to the professional grindstone made of high-tech materials, this field has experienced a long and brilliant development process. Today, we will focus on a special product -8x 2x 1 inch five hulan box grade 1 black silicon carbide whetstone, and explore how it has become a secret weapon in the hands of professionals.

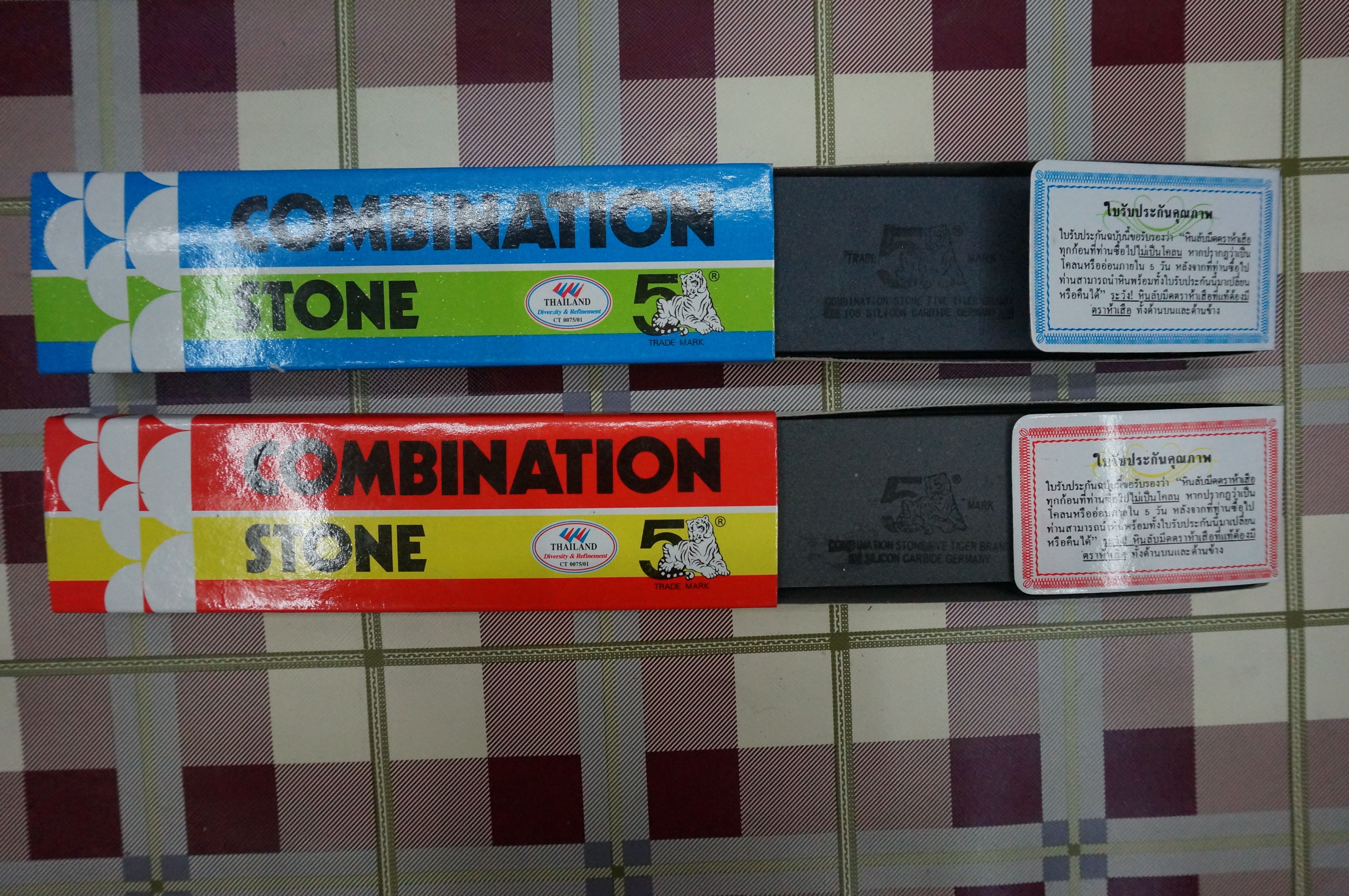

Compared to ordinary sharpening stones, black silicon carbide stands out due to its unique physical properties and excellent processing capabilities. This material is not only extremely hard, but also has excellent cutting efficiency and durability, making it the tool of choice for many cooks and craftsmen. In particular, it is worth mentioning that this grindstone uses the top quality of the first grade black silicon carbide raw materials, further improving its comprehensive performance.

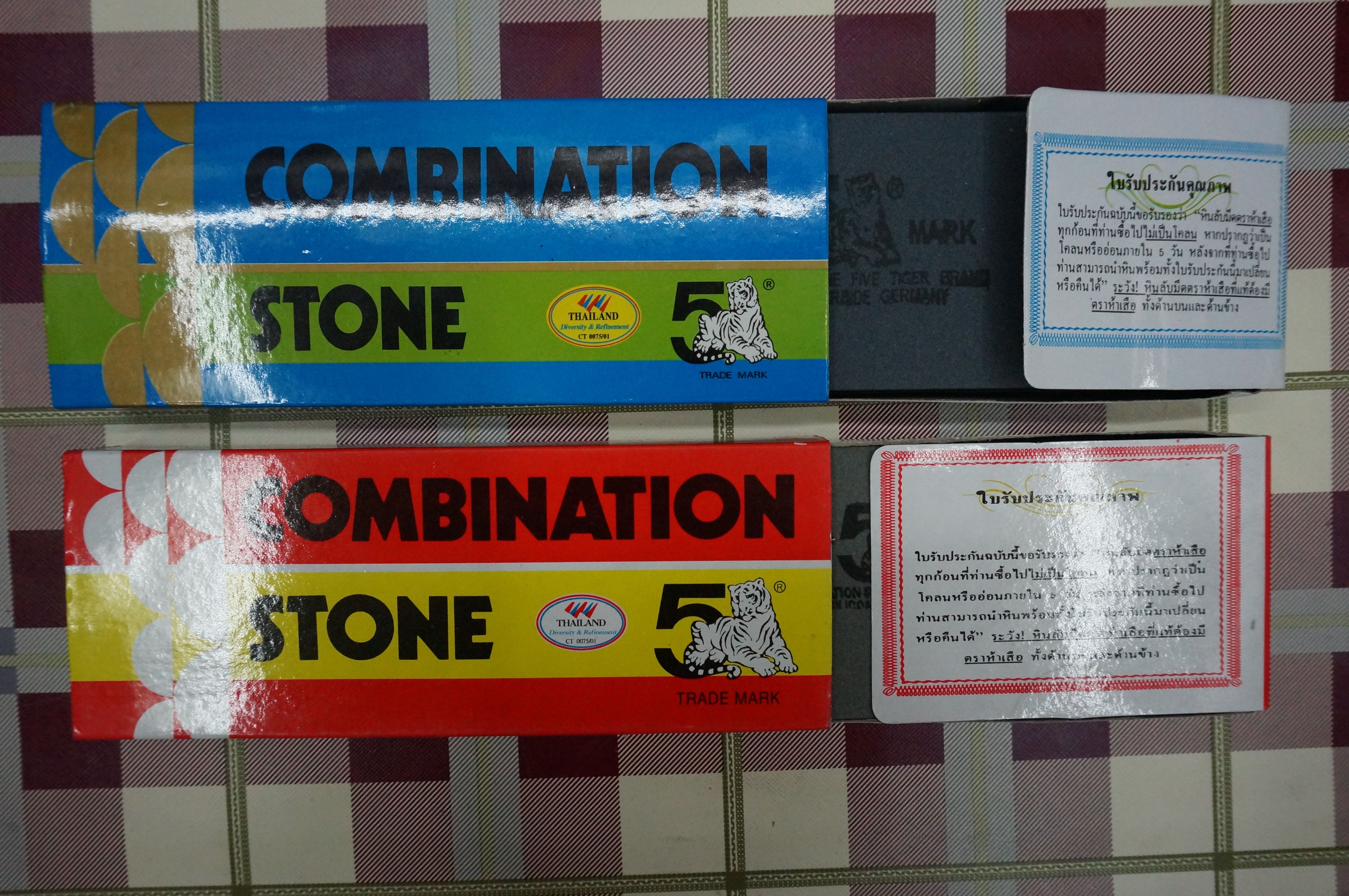

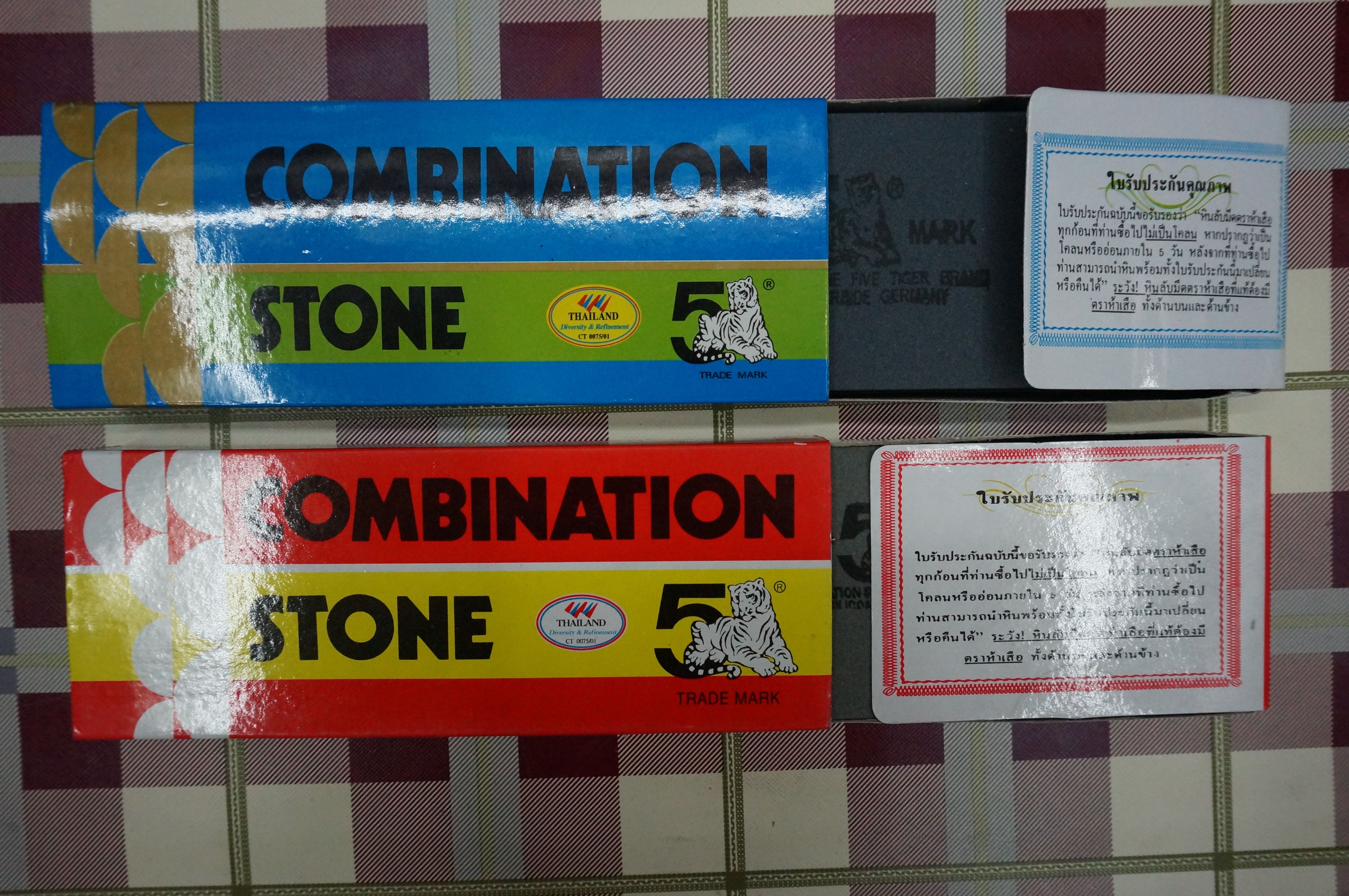

According to the individual needs of different users, the product is designed with a precise standard size -8x 2x 1 inches, which is matched with the classic five-hulan box packaging form, which is easy to carry and store. This specification setting is very suitable for most scenarios, whether it is kitchen knife trimming in the home kitchen or complex hand carving tasks can be easily handled.

In-depth study of its internal structure, you will find that the first-class black silicon carbide hides many scientific principles. Through advanced sintering technology and precise control of particle distribution, the surface presents a uniform effect. Every friction action is like a micro-carving project, reshaping the cutting edge to be smoother and sharper.

In the home environment, this grindstone can quickly restore the function of a passivated kitchen knife. In a professional carpenter's workshop, it can accurately adjust the shape of the serration or the angle accuracy of the small carving knife. The two distinct uses demonstrate their wide adaptability.

For the best user experience, please follow the correct usage process. It is first necessary to wet the entire work area with water (if it is of the wet type), and then to move the object to be treated back and forth at an appropriate angle until it is satisfactory. Remember not to use too much force to avoid damage to yourself or the equipment itself.

In order to extend the service life and maintain a good condition, daily care is equally important. After each operation, the residue shall be removed in time and stored in a cool and dry place to prevent deterioration caused by moisture.

Good reviews from all sides have verified the reliability of this product. "The cutting becomes so smooth!" A housewife who has long relied on the grindstone lamented, "All my knives are now as new as they are." Another experienced iron artist said: "This thing saves me a lot of time and energy, especially in the details."

Of course, there are a few key things to keep in mind before buying to ensure that you buy the product that best suits your situation. This includes, but is not limited to, confirming whether the specific model meets the intended use, understanding the merchant's after-sales service policy, and checking whether other accessory combinations are available.

Looking ahead, as new materials and technologies continue to emerge, the cutting tool maintenance industry will also usher in more possibilities. Perhaps one day we will see fully automated and even intelligent solutions appear, but now having such a good grindstone is enough to meet the needs of most people.