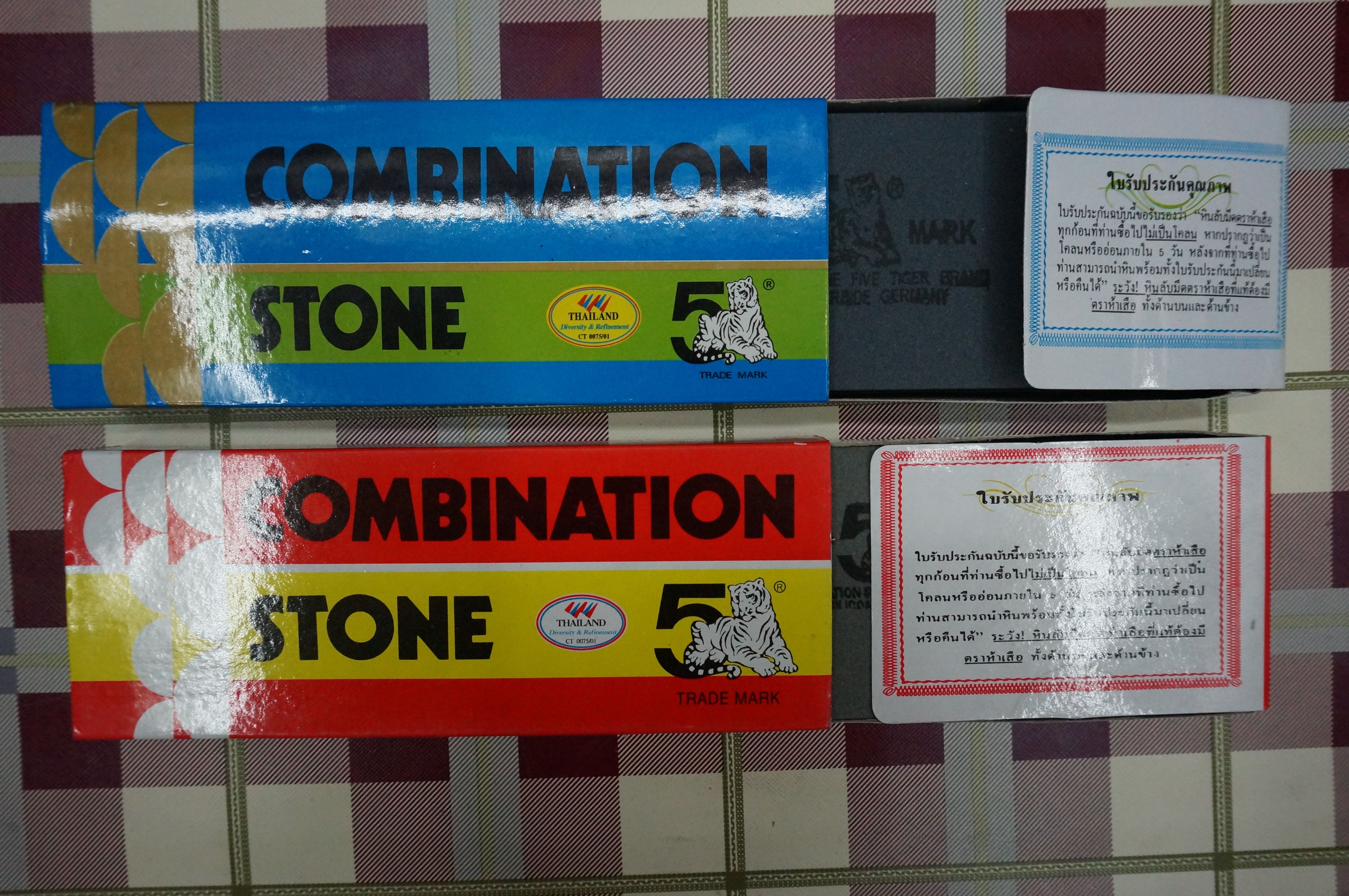

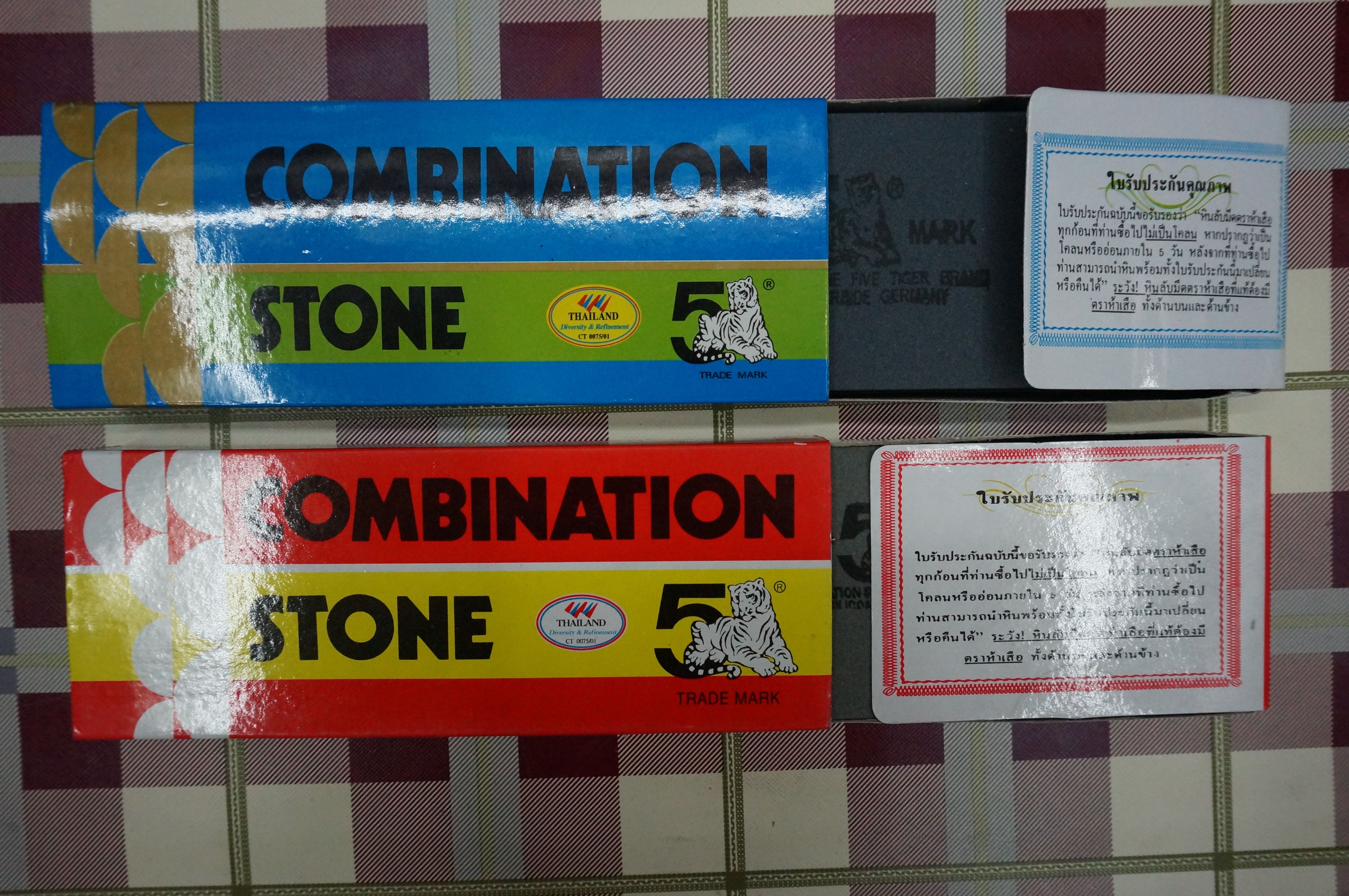

The sleek, professional-grade black silicon carbide whetstone — where craftsmanship meets cutting-edge material science.

The Science Behind Sharpness: How This Black Stone Is Redefining Grinding Rules

In a world where tools are only as good as their edge, one unassuming block is quietly revolutionizing how we think about sharpening. From the dimly lit garage workshops of master woodworkers to the high-pressure kitchens of Michelin-starred chefs, and even in the rugged backpacks of outdoor survivalists, this 8x2x1 inch five-hole black silicon carbide whetstone has become the trusted companion for those who demand perfection from their blades.

From Garage Workshops to Gourmet Kitchens — A Stone That Transcends Boundaries

Imagine a woodworker restoring an antique hand plane, its blade dulled by decades of neglect. With steady hands and focused breath, he draws the iron across the stone — each pass revealing a renewed gleam. In another scene, a chef preps for dinner service, slicing through ripe tomatoes with a knife that glides like silk, thanks to a quick touch-up on the same compact stone. And miles away, a hiker sharpens his survival blade beside a mountain stream, relying on a tool as dependable as the terrain is unpredictable. This is not just a whetstone — it’s a bridge between purpose and performance.

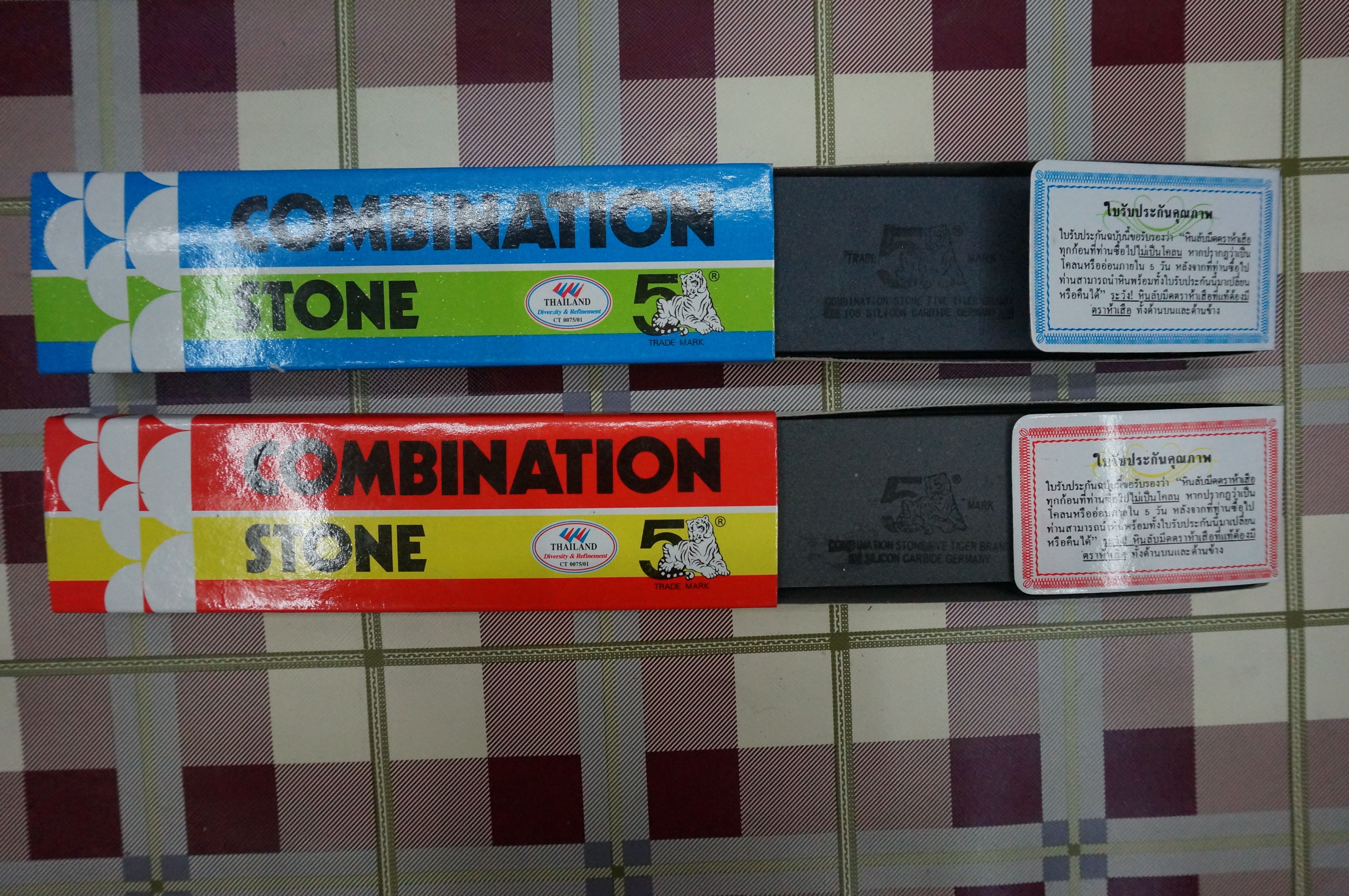

Precision in motion: The carbonized surface delivers consistent abrasion for both delicate kitchen knives and rugged outdoor tools.

The Secret of the Black Crystal: Why Silicon Carbide Reigns Supreme

Beneath its dark, almost metallic sheen lies a material forged under extreme heat — silicon carbide, a synthetic abrasive nearly as hard as diamond. Unlike traditional aluminum oxide stones that wear down quickly or natural whetstones that require meticulous maintenance, this black stone offers unmatched hardness and thermal resistance. It cuts faster, lasts longer, and maintains uniform grit throughout its life. Whether you're working with high-carbon steel or modern stainless alloys, it bites efficiently without loading up or glazing over.

More Than Just Size: The Engineering Wisdom Behind 8x2x1 Inches

Every dimension of this whetstone has been optimized for real-world use. At 8 inches long, it provides ample surface area for full-length strokes, reducing edge roll and ensuring even wear. The 2-inch width offers stability during aggressive grinding, while the 1-inch thickness gives it the mass needed to stay firmly in place — no wobbling, no slipping. It fits perfectly on any countertop, workbench, or field-ready setup, making it equally at home in a professional kitchen or a portable toolkit.

The Philosophy of Five Holes: Where Function Meets Flow

The five precisely drilled holes aren’t just aesthetic — they’re functional genius. Designed to channel water and metal swarf away from the grinding surface, they prevent clogging and maintain consistent contact between blade and stone. They also serve as reference points for flattening the stone when needed, using sandpaper on glass — a simple yet vital maintenance step often overlooked. These perforations ensure that whether you're doing a quick touch-up or a full reprofile, the surface remains efficient and predictable.

Top-down view highlighting the symmetrical five-hole design — engineered for drainage, calibration, and sustained performance.

Wet, Dry, or Anything In Between — This Stone Adapts to You

While many abrasives falter outside their preferred lubrication method, this silicon carbide stone thrives in both wet and dry conditions. Use water for cooler, cleaner sharpening with visible slurry control, or go dry for quick field adjustments when liquid isn't available. Its non-porous structure resists absorption, preventing bacterial growth and minimizing mess. Cleanup? A quick rinse is all it takes.

From Coarse Rebirth to Fine Refinement — One Stone, Multiple Stages

You don’t always need a full set of stones to achieve razor precision. While classified as a coarse-to-medium abrasive, skilled users can modulate pressure and angle to transition from shaping a damaged edge to refining a polished bevel. Pair it with lighter stones later if desired, but start here — because true sharpness begins with a strong foundation.

Proven by Time: When “Durable” Means Something Real

Accelerated wear tests show minimal surface degradation even after hundreds of sharpening cycles. Unlike softer stones that hollow out or become uneven, this silicon carbide block wears flat and predictably, maintaining its effectiveness year after year. It’s not just built to last — it’s built to perform consistently over time.

The Hidden Details That Make All the Difference

Notice the slightly chamfered edges — designed to prevent chipping and extend usability. Feel the textured bottom pattern — a subtle anti-slip feature that grips your mat or tray without scratching surfaces. These small touches reflect a deep understanding of how people actually use tools, not just how they’re supposed to.

From Forge to Table: The Sensory Journey of a Blade Reborn

Picture a once-dull chef’s knife, struggling to mince garlic. After several deliberate passes across the black stone, something changes. The metal sings against the abrasive. Shavings form. The edge catches the light differently. Then, the test: a clean slice through paper. A tomato skin parts without pressure. The blade doesn’t cut — it flows. This is more than restoration; it’s resurrection.

More Than a Tool — A Symbol of Modern Craftsmanship

In an age of disposability, choosing to sharpen — to repair, to refine — is an act of intention. This whetstone embodies that philosophy. It doesn’t promise magic. It delivers reliability, precision, and respect for the craft. For the artisan, the cook, the adventurer — it’s not just about sharper tools. It’s about deeper focus, greater care, and the quiet pride of mastery passed one stroke at a time.