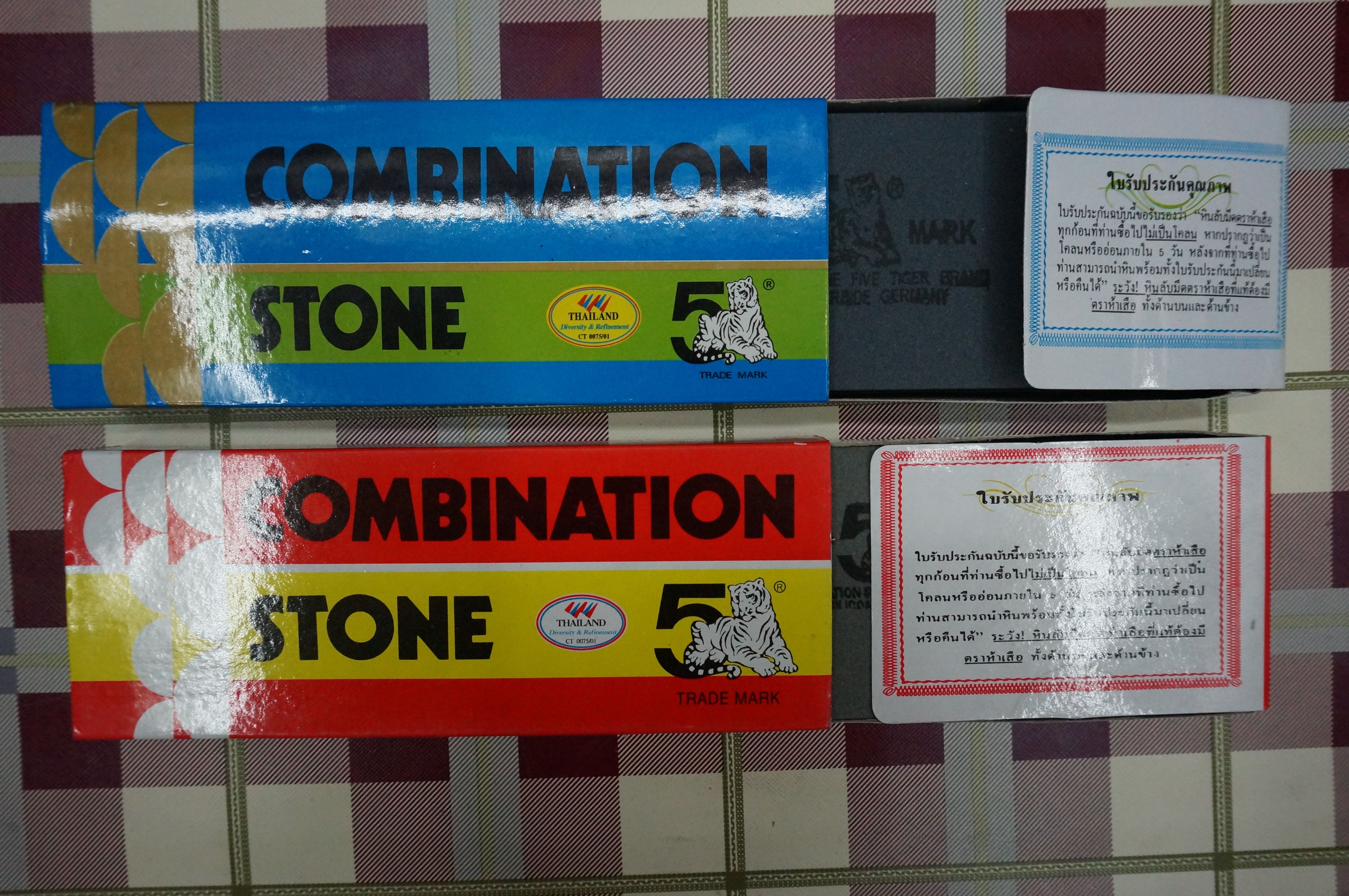

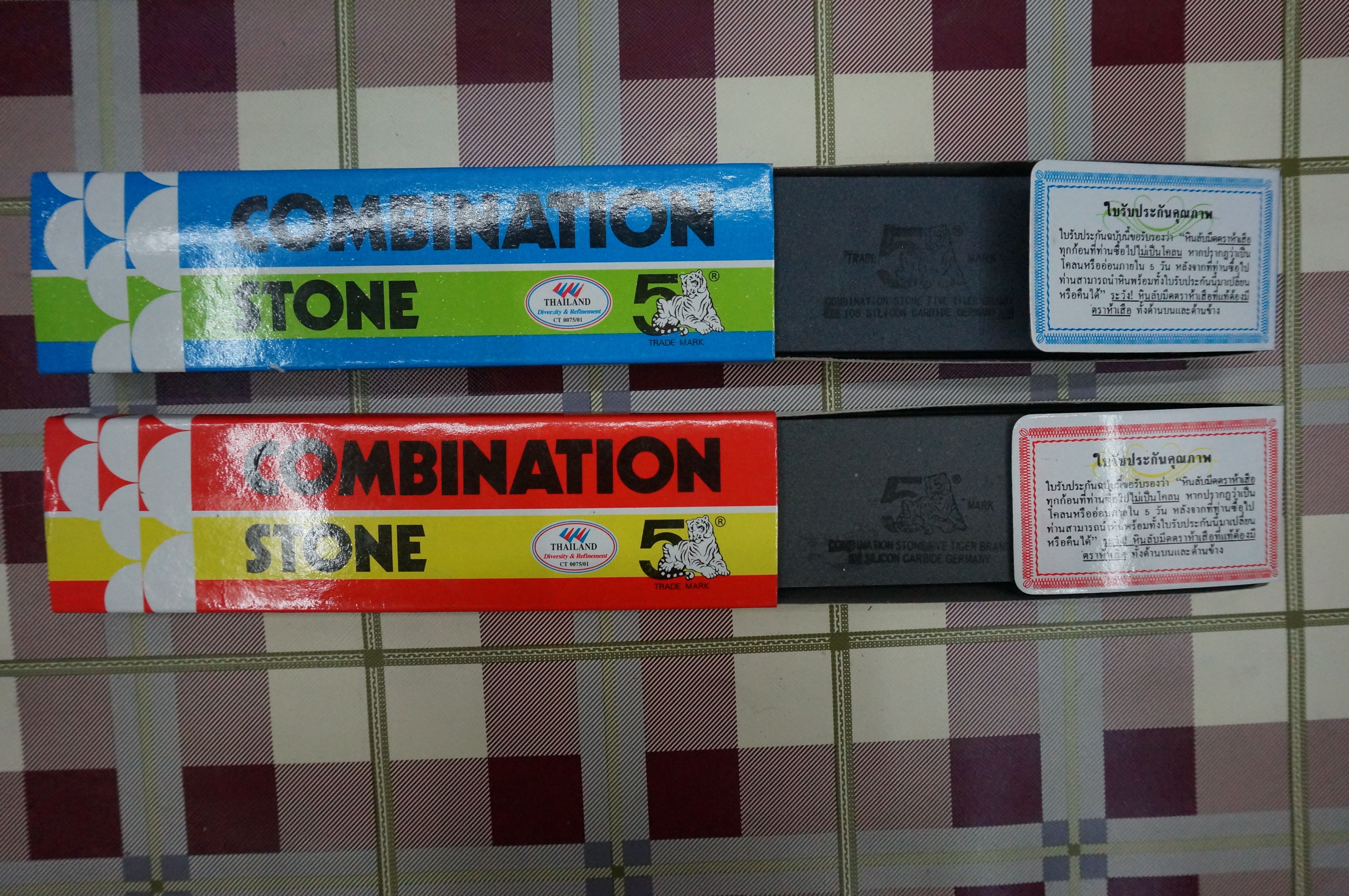

Professional-grade Sharpening Solution for Reinventing Sharpness Reproduction

In daily use, whether it is a kitchen knife in the kitchen or a variety of cutting tools in the process of repair will gradually lose their original sharpness due to wear. This first-class black silicon carbide grindstone for precision grinding brings you lasting and stable grinding performance with its excellent hardness and uniform particle distribution, so that every passivated tool will shine again.

Scientific size design takes into account practicality and ease of handling

the unique 8x 2x 1 inch specification fully takes into account the user's holding habits and the needs of operating space. it is small but functional. it can not only flexibly cope with small blades, but also stably handle large area trimming work. it is very suitable for household cooking enthusiasts or professionals who need high-frequency maintenance equipment.

The core abrasive material derived from natural minerals has significant advantages

The black silicon carbide, which is mined by selecting deep ore layers and purified by high temperature calcination, has extremely high compressive resistance and thermal stability. Even if it is operated continuously for a long time, it is not easy to produce deformation loss, so as to ensure that every friction process can achieve the expected effect, greatly extend the service life and reduce the replacement cost.

Meticulous grading system meets varying degrees of edge repair challenges

for different situations that have been seriously damaged or just want to do fine-tuning and optimization, this sharpening stone is equipped with a reasonable particle size gradient, so that rough grinding, polishing and final finishing can be completed in one step, and all processes can be completed without switching multiple accessories. while saving time and energy, it also reduces the threshold required to learn and master skills, allowing more people to enjoy smooth cutting pleasure as new.

Wide application compatibility and strong coverage of diverse industry needs

in addition to common cooking scenes, the product also shows strong potential in woodworking carving, metal processing and other fields. whether it is hard alloy serrated teeth or household shears made of soft steel, it can quickly restore its best condition under its action, becoming an indispensable good helper for professionals to maintain efficiency, and also an ideal supplement for DIY people to improve their personal studio configuration.

Humanization considerations extend more value-added experiences

considering the problems such as sliding deviation that may occur in actual application, the surface texture has been specially improved to make it have stronger adsorption force and prevent damage caused by accidental touch. In addition, it can also be adapted to a special fixed base (if any) to further improve safety, especially suitable for novice friends who first contact with manual polishing to build confidence faster and enjoy the whole production journey calmly.

Environmental protection manufacturing standards practice the concept of green sustainable development

The principle of energy conservation and emission reduction is always adhered to throughout the production chain. Every link from raw material acquisition to finished product packaging strives to minimize the footprint of environmental pollution, while eliminating the addition of heavy metals and other toxic ingredients, so as to ensure that the final delivery to consumers is not only high-performance goods, but also a good witness bearing the sense of social responsibility.